In this blog, we describe the process for building and installing a water control structure called an open-top box culvert on forest roads at Clearpool Model Forest.

When fast-flowing water runs across a forest road, it can cause erosion and carry sediment into local waterways. Water quality best management practices (BMPs) include water control structures that can minimize erosion and sediment runoff from roads, helping to protect aquatic habitats and drinking water quality and maintain road surfaces.

BMPs don’t need to be complicated to be effective. In fact, with the right materials, you can build and install your own BMPs. In this blog, we’ll go through the process of building and installing a simple type of BMP called an open-top box culvert on a gravel road at Clearpool Model Forest.

Think of an open-top culvert like a long, narrow box without a lid. When installed across a forest road, the open top collects water and debris, diverting it off the road where it’s less likely to cause erosion and sedimentation. Open-top culverts can be made from old pipes, small diameter logs called poles, or in this case, pressure-treated boards.

Three different types of open-top culvert. (Left) Made from a pipe. (Center) Made from pole logs. (Right) Made from pressure-treated boards.

We identified spots on forest roads in the Clearpool Model Forest where rapid water flows tend to carry sediment downslope off the road, then measured the width across the road at a slight downward angle rather than fully perpendicular – the downward angle helps direct water into the culvert as it flows. We’ll build our culverts to be slightly longer than the width of the road, so they’re sure to carry water and debris away from the road surface.

All the supplies we needed to build our open-top box culvert were available from local hardware stores or online suppliers. For each culvert, we needed:

- 72 galvanized flat washers

- 12 galvanized hex nuts

- 12 five-eighths inch by 14-inch coarse thread hex bolts

- 64 two-and-a-half-inch wood screws

- 6 eight-foot long, four-by-six-inch pressure-treated boards

- 2 twelve-foot long, two-by-twelve-inch pressure-treated boards

- 4 feet of one-inch steel pipe

The total cost for the supplies for one culvert was around $600. We built and installed three of these.

For tools, we gathered a power drill with a three-quarter-inch spade bit, a grinder to cut the steel pipe, a saw to cut the boards to length, a wrench set, measuring tape, pencils, and safety gear including work gloves and eye protection.

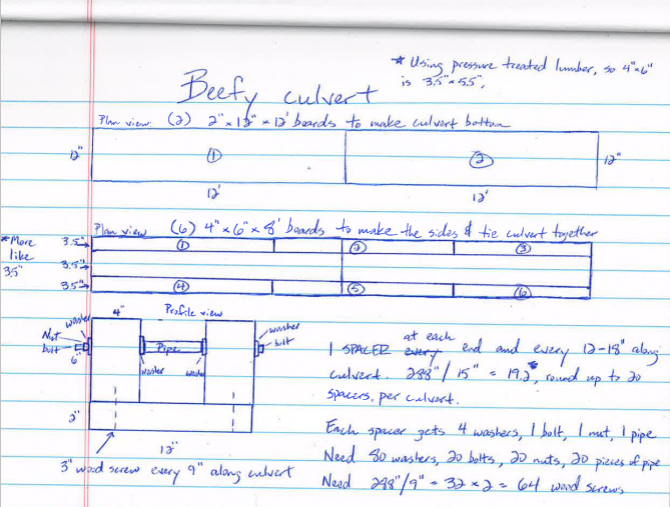

Kris Brown drew up plans to help with culvert construction. The two-by-twelve-inch boards were used for the bottom of the culvert, and the four-by-six-inch boards became the sides. We used wood screws every 9 inches to attach the sides to the bottom.

Kris’s plans for building the culvert.

The assembled culvert bottom and sides.

To stabilize the culvert and prevent it from collapsing, we installed pieces of one-inch steel pipe that were cut to fit snugly inside the culvert every 24 inches along the entire culvert length, using washers, hex bolts and hex nuts to firmly attach them. We made sure there was a piece of pipe installed at each end of the culvert to further stabilize it.

Measuring the width inside the culvert to cut steel pipe to length.

Completed culverts, ready for installation.

With the culvert built, it was time to install. We dug a trench in the road where we wanted to put the culvert, then sank the culvert in. Each assembled culvert was 24-feet long and very heavy, so we used a backhoe to lift the culverts and drop them into place. It sometimes took several tries to ensure the culvert sat just below the road surface and had just the right amount of “fall” - downward slope that allows runoff to drain across and off the road. It’s important to install open-top culverts with just enough “fall” and flush with the road surface so runoff can easily flow into them and vehicles can drive smoothly over them.

Installing the culvert.

Installation complete.

When open-top culverts do their jobs well, they eventually collect sediment and debris that otherwise would have run down the road into local waterways. That means we need to maintain them to keep them in working order. The easiest way to do this is to grab a trowel, small shovel, or even just a sturdy stick that fits inside the culvert and use it to push the debris in the culvert toward its outlet. This can be a great excuse to spend an hour out in your woods, listening for birds and enjoying the scenery while getting a good light workout. You can learn more about culvert maintenance in this 2022 blog post: Maintaining Forestry BMPs is Good for You and Water Quality.

DIY BMPs like this one are a great opportunity to interact with your land and protect water quality. Next time you’re walking through your woods, keep an eye out for pathways and roads that look washed out or eroded – these are great places to consider installing BMPs.

Curious about other types of BMPs? The New York State Forestry BMP Field Guide is a great resource for learning about types of water control structures, where they’re most useful, and how to build and install them to protect your water and your woods.